Guda Product Quality System

A product quality system

01

Product Quality: Cornerstone of Guda

To ensure that our products meet the highest standards, our group has established a specialized Quality Inspection Center. We rigorously oversee three critical aspects of product quality: raw material procurement, equipment acquisition, and production testing technology. Adhering strictly to national standards in production and quality technology testing, we meticulously scrutinize the quality of every meter of cable.

02

Comprehensively Implementing Total Quality Management (TQM)

Our group has independently devised and implemented the Product Quality Assessment System, establishing a performance evaluation mechanism centered around product quality assessment. Beginning with meticulous attention to detail, we deconstruct the production processes of electrical wires and cables, tailoring measures to address product quality defects at each stage, and ensuring the safety of our product quality.

03

Strict Adherence to the “Self-inspection”, “Mutual Inspection”, and “Special Inspection” System

Our group has instituted an inspection system that combines self-inspection, mutual inspection, and special inspection. Vernier calipers and outside micrometers are allocated to every position, facilitating layers of checks to eradicate quality issues within internal management procedures, and guaranteeing the quality compliance of every meter of cable.

Technological Research and Development Achievements

Lead display

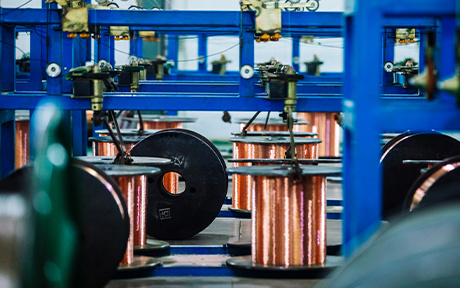

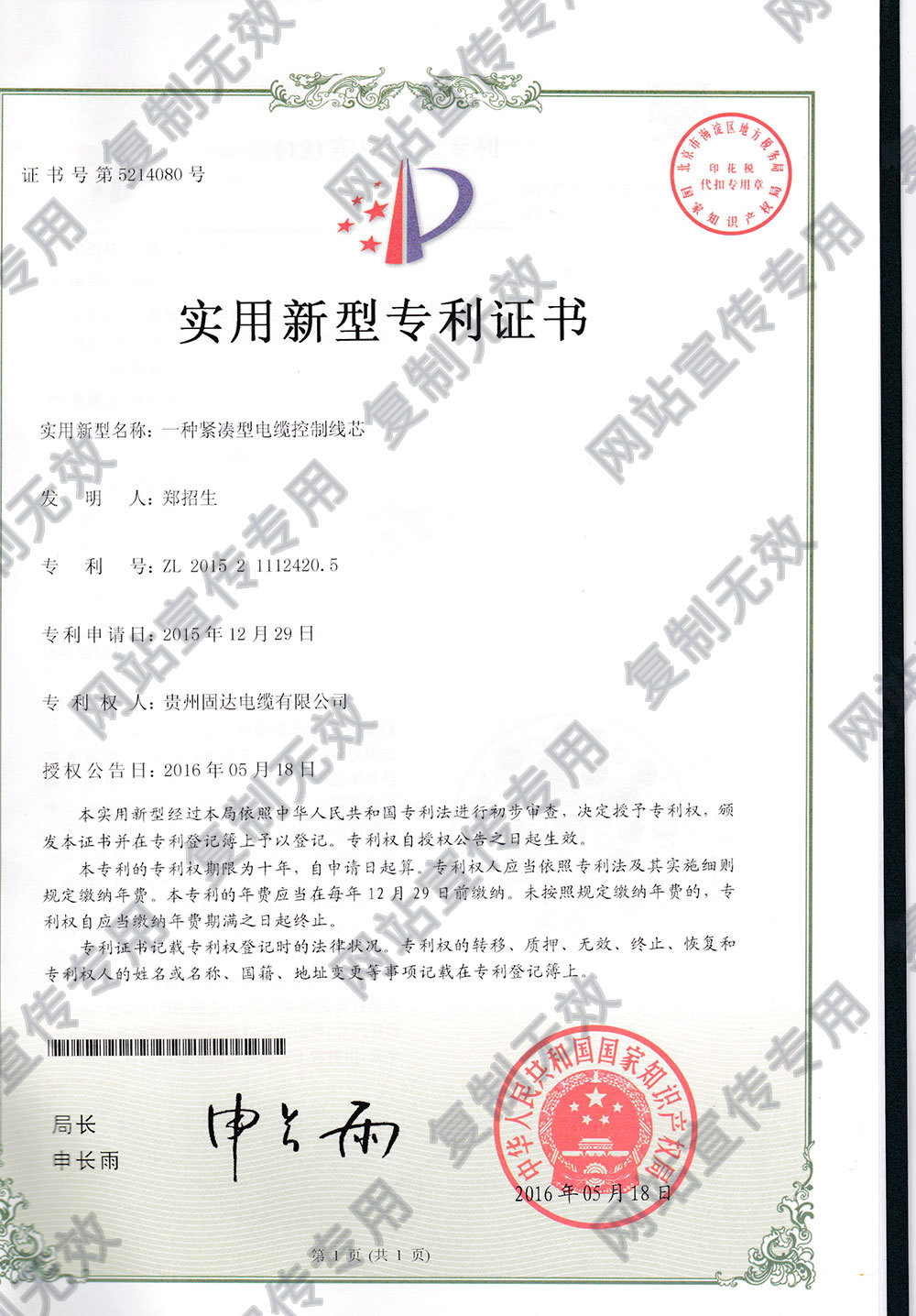

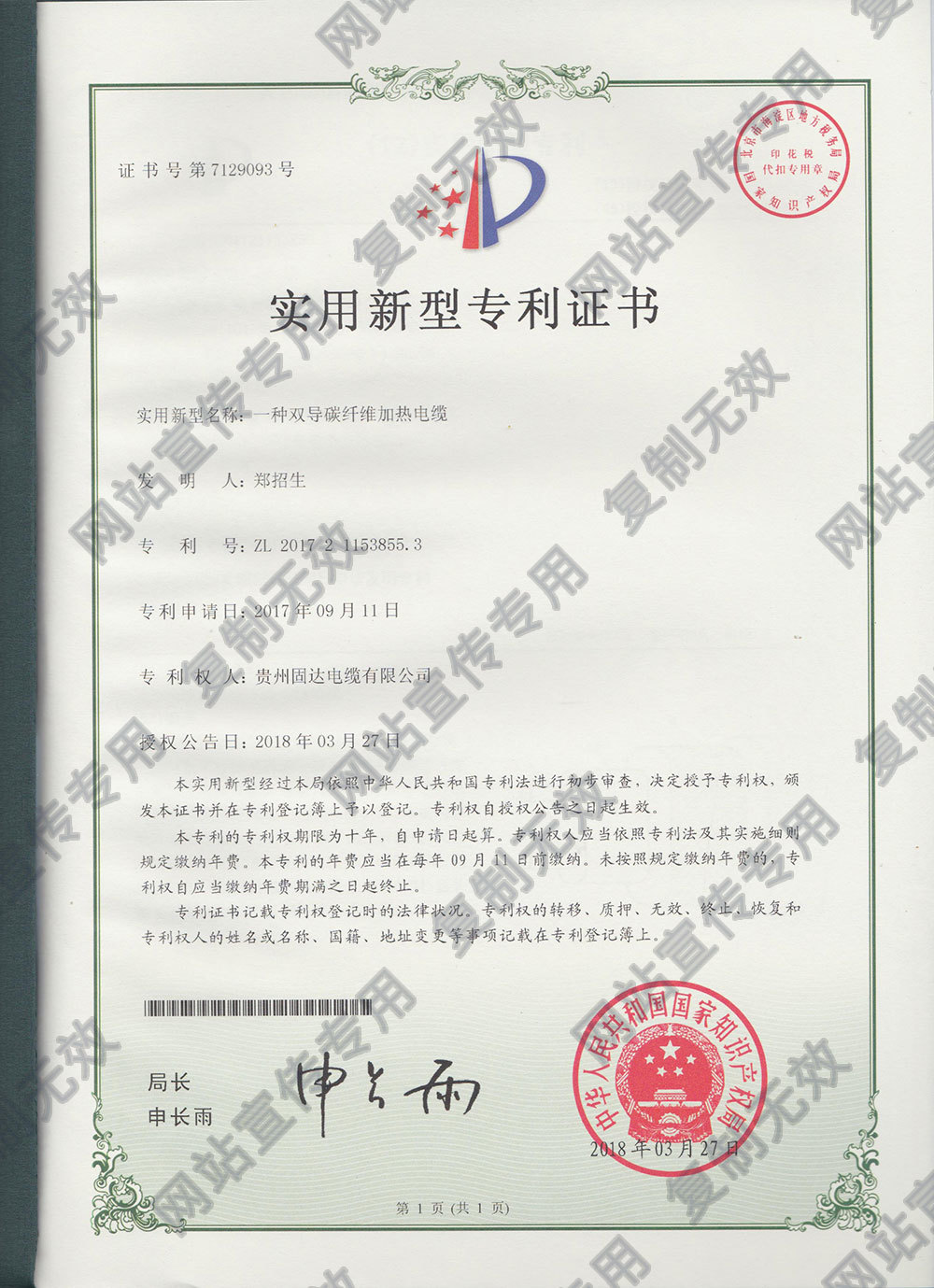

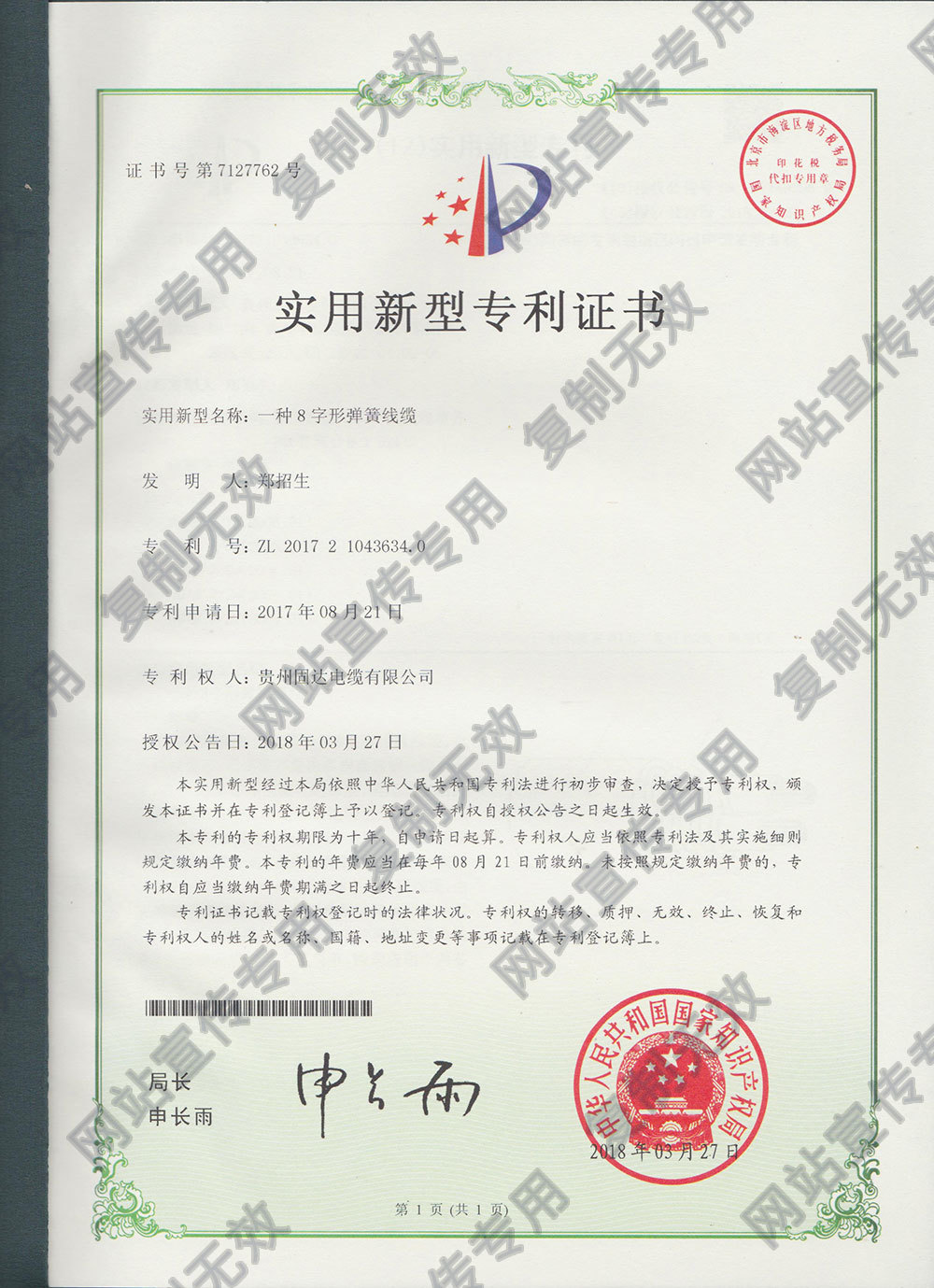

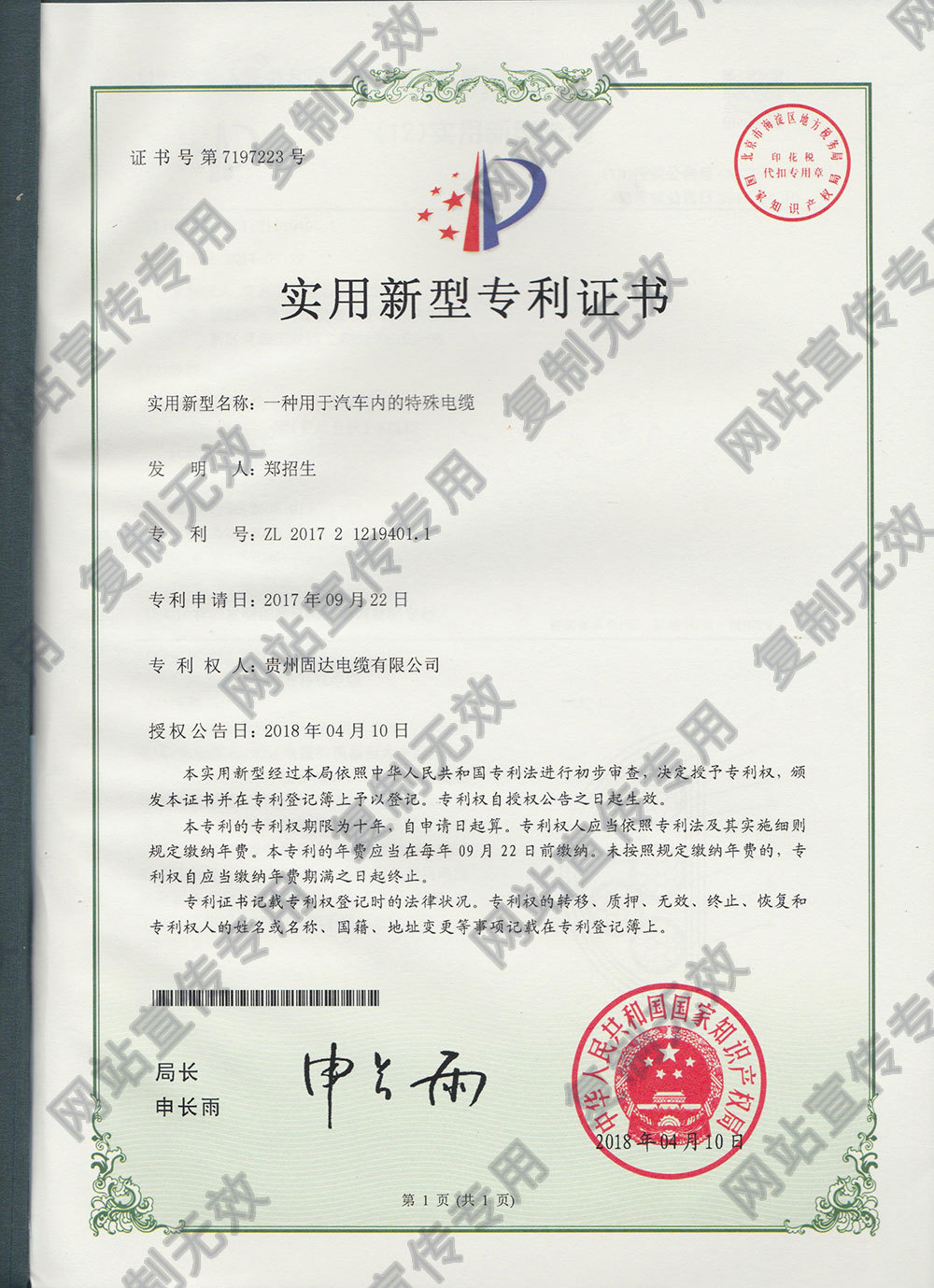

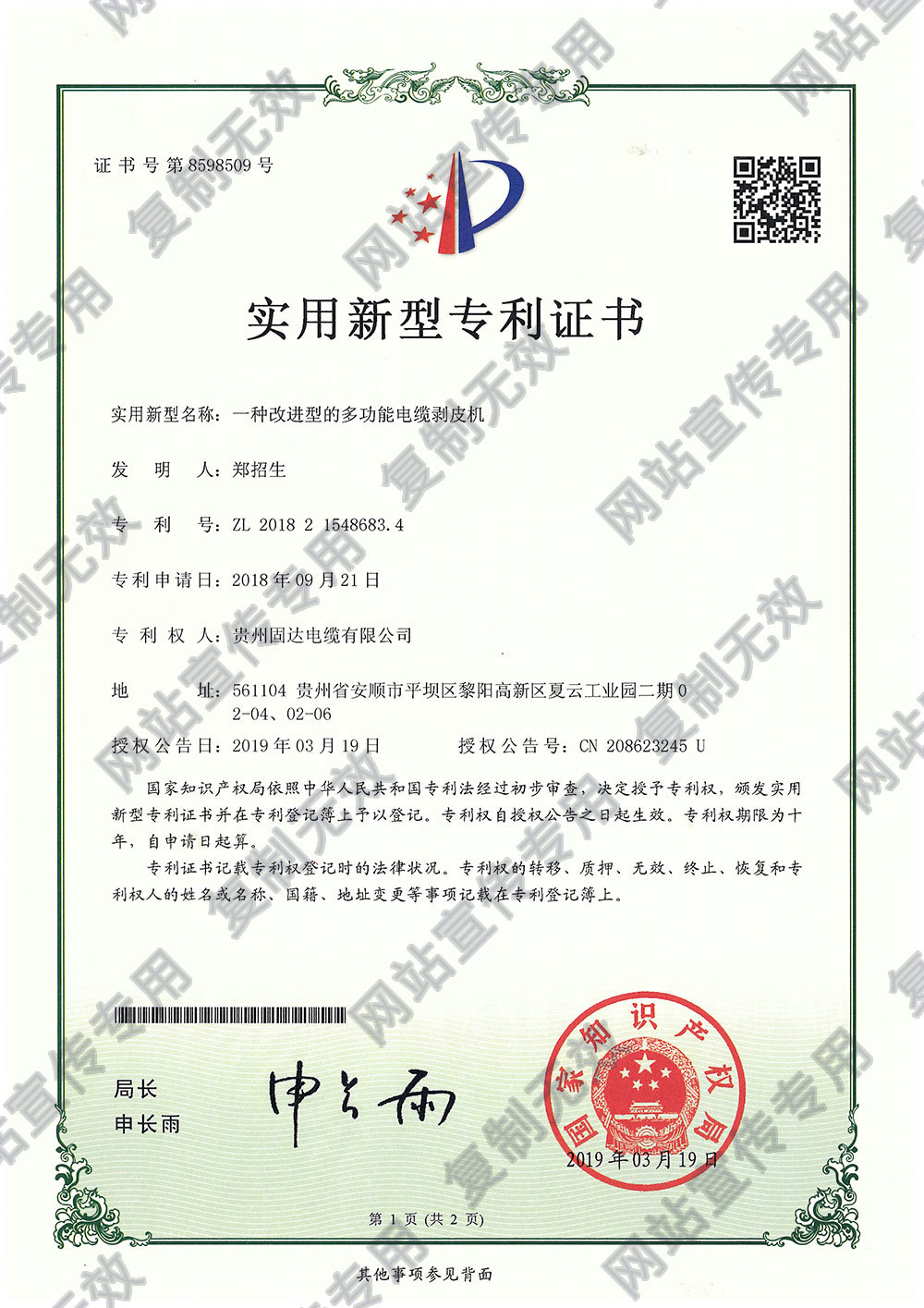

Guda Cable Group strictly adheres to national industrial policies and standards for wires and cables, continually advancing its production capabilities through the adoption of cutting-edge domestic equipment and technology. Over six years of development, our company has remained steadfast in its commitment to quality, prioritizing technological innovation. Presently, we boast over 30 utility model patents, with numerous invention patents currently in the application pipeline.

In 2018, we intensified research and development investment and achieved breakthrough through collaboration with Guizhou University on the development of “Mineral Insulated Flexible Cables”. Recruiting a Chief Technology Officer and assembling an elite technical research and development team, including several Ph.D. holders and experts from College of Materials and Metallurgical, Guizhou University, we currently employ 23 research and development personnel holding professional titles. Our endeavors encompassed the application for projects such as the Science and Technology Innovation Category of the Science and Technology Department in 2018 and the prestigious “Leading Enterprise” accolade in 2019. We have been honored with honors such as the “Provincial Enterprise Technology Center” by the Ministry of Industry and Information Technology.

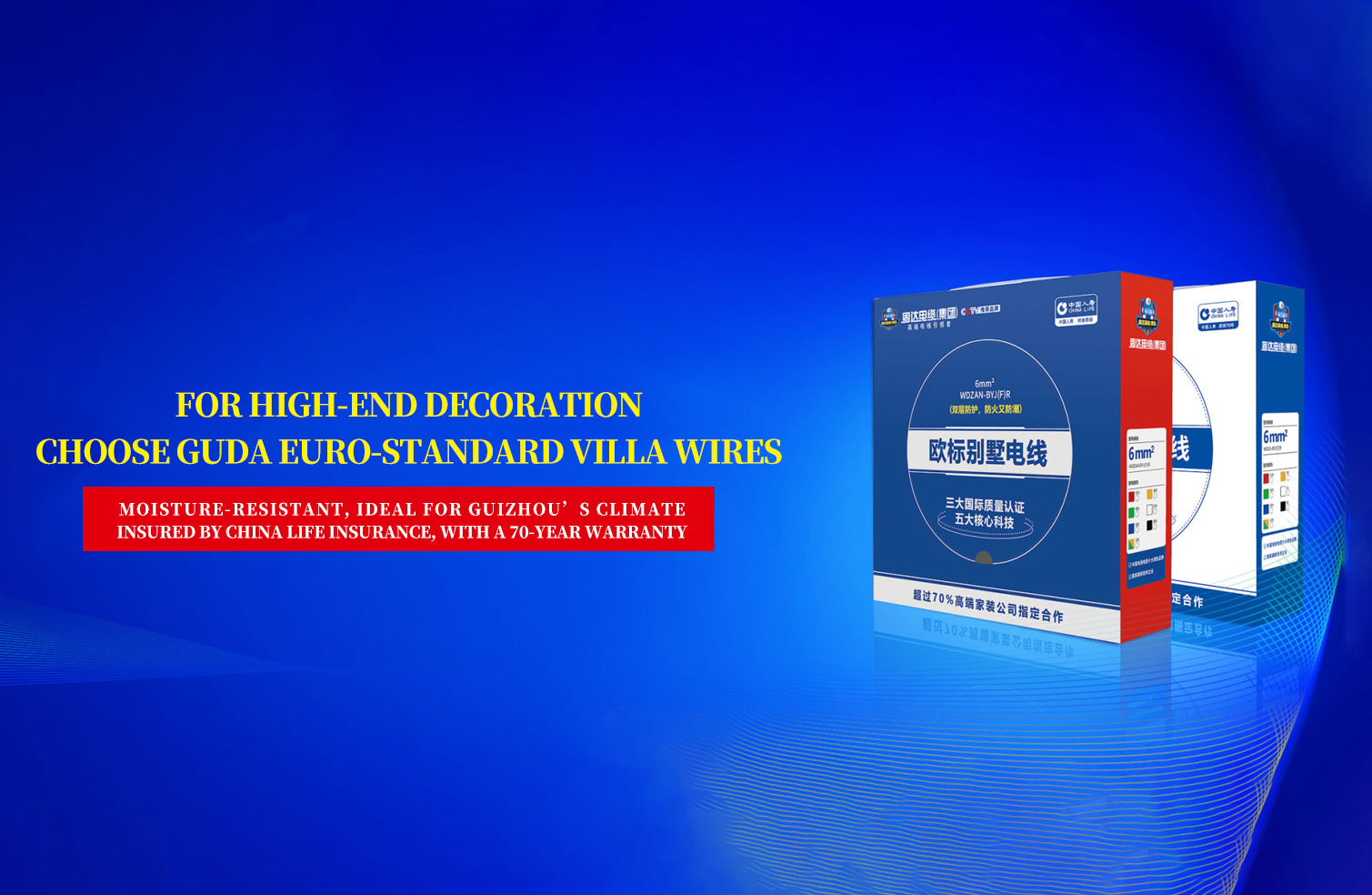

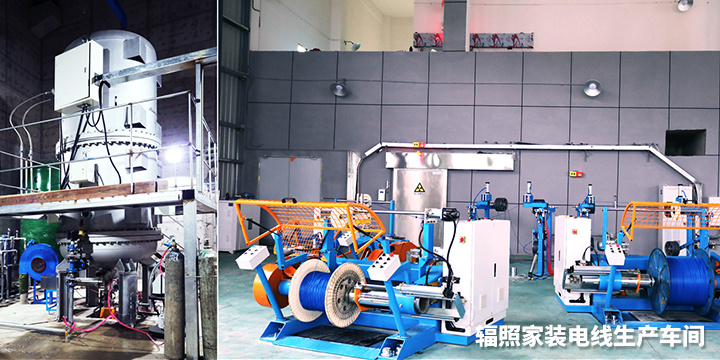

In 2019, our group made substantial investments in an irradiation wire production workshop, introducing irradiation cross-linking equipment from Russia. This facilitated the launch of high-quality household wires tailored for villas and high-end residences—Euro-standard villa wires and eco-friendly household wires. With a product lifespan of up to 70 years, synchronized with property certificates, this initiative opened a new era in the Guizhou household wire market, propelling the rapid development of the cable industry in the region.

The newly constructed workshop in 2019 features multiple production lines and equipment, expanding our company’s product range. Three key categories—including irradiation particle accelerators, flexible fire-resistant cable production lines, and medium-voltage cable production lines—have significantly propelled the overall cable industry in Guizhou, spearheading its rapid advancement.

With an annual investment of approximately 12 million yuan in research and development, we dedicate substantial human, material, and financial resources to innovating and developing new products that align with market demands and future requirements, laying a robust foundation for the company’s continued growth.

Guda R&D Patents

Guda R&D Patents

Patent for a compact cable control core

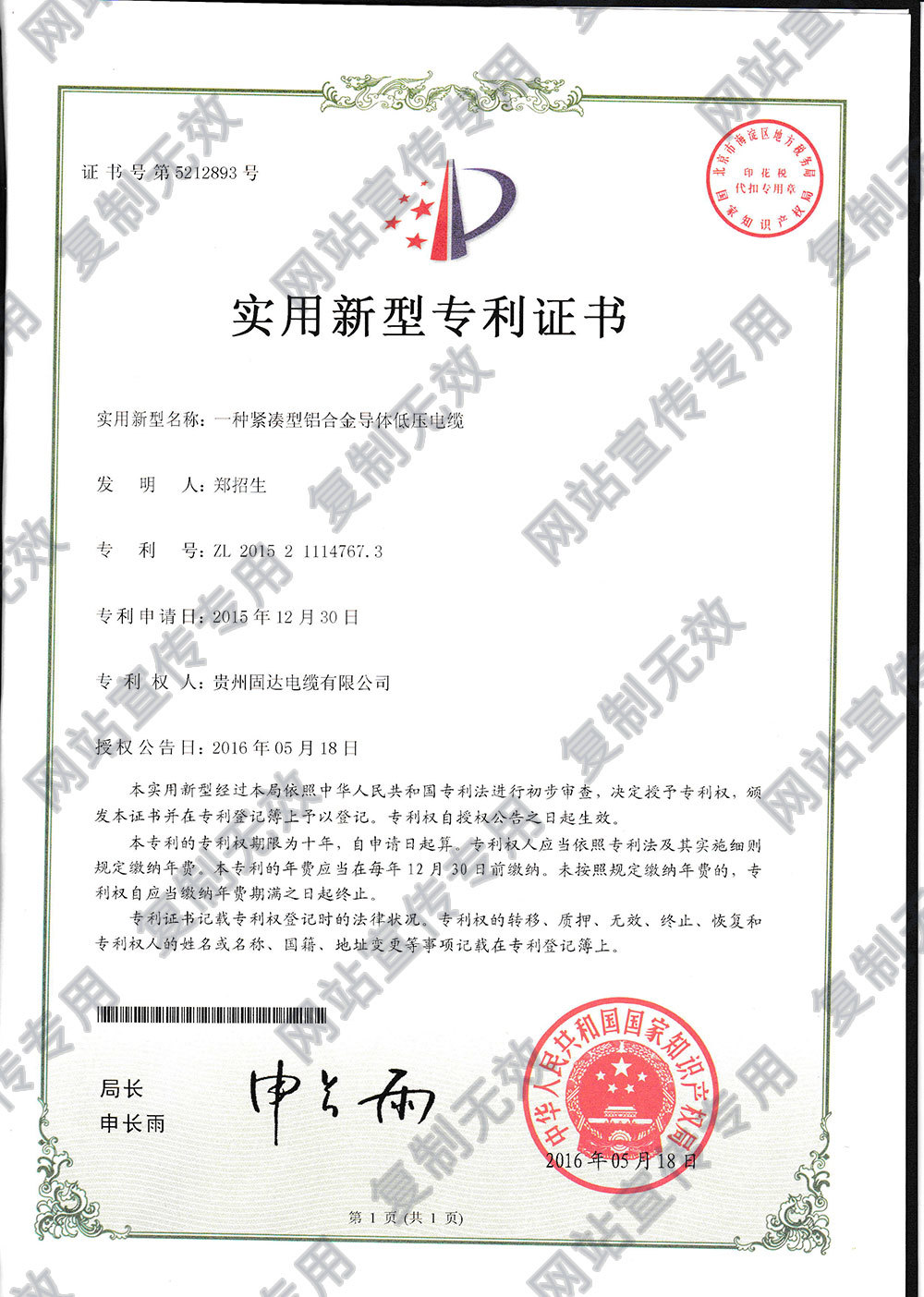

Patent of a compact low-voltage cable with aluminum alloy conductor

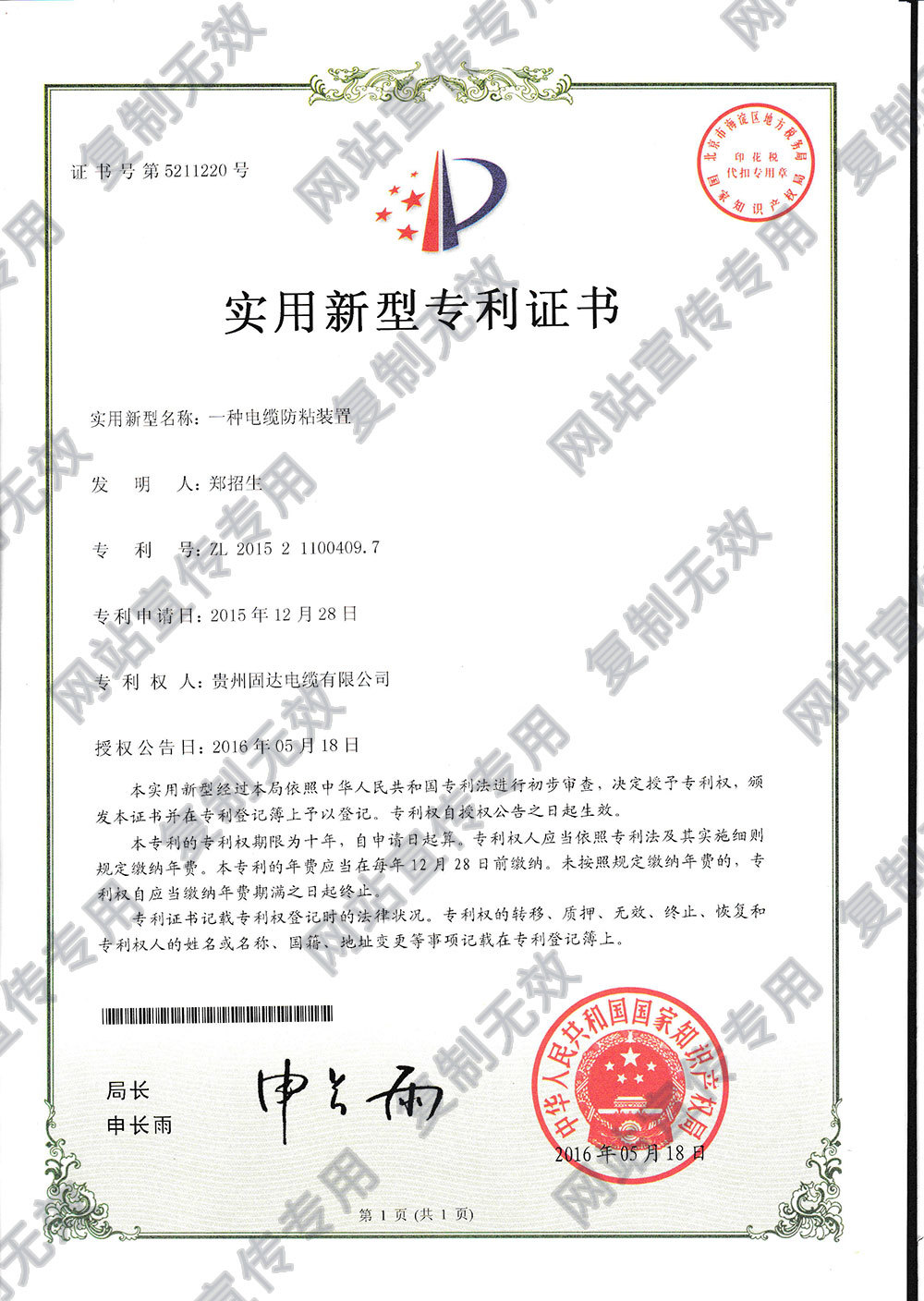

Patent of cable anti-sticking device

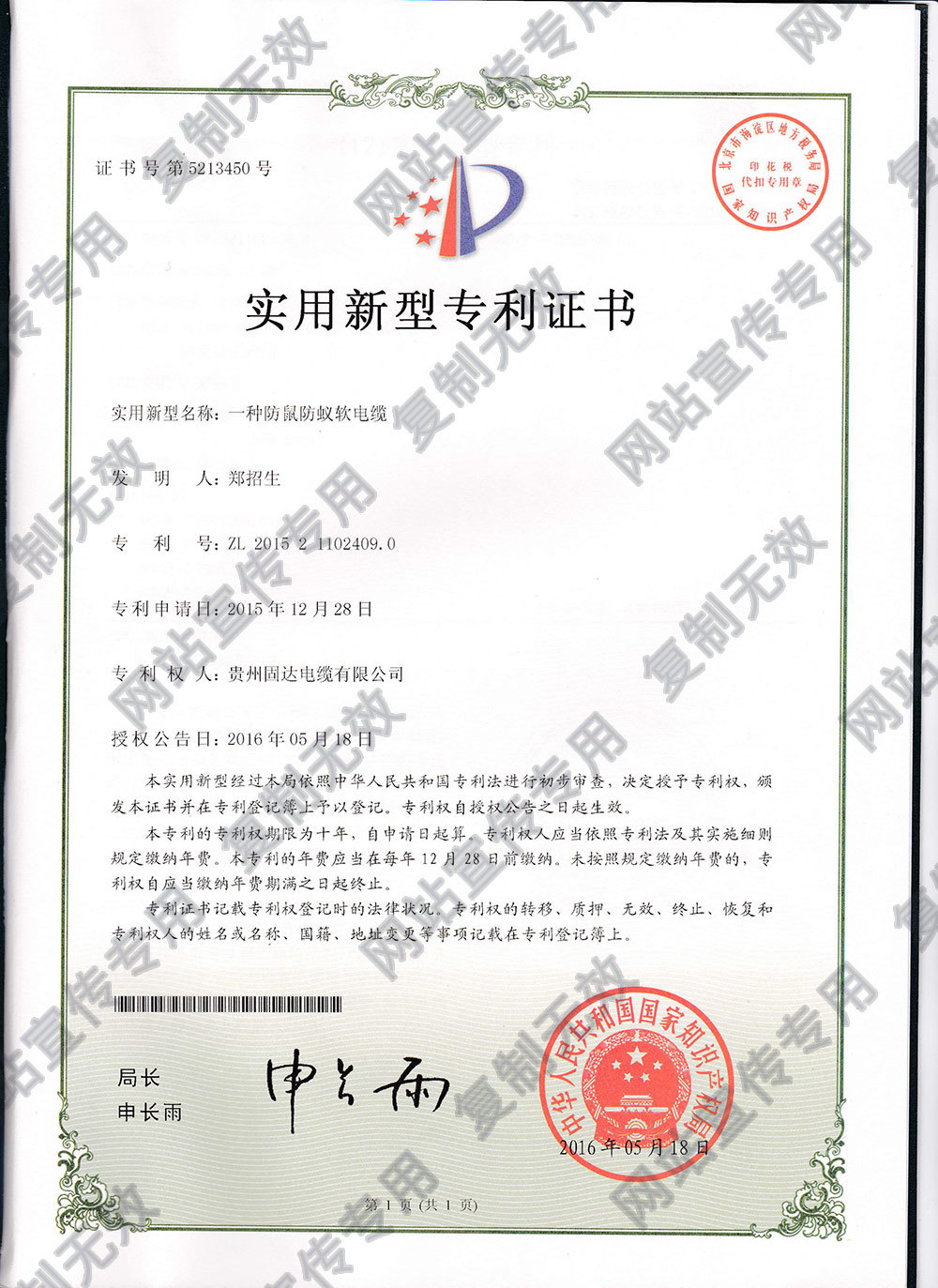

Patent of anti-rat and anti-ant soft cable

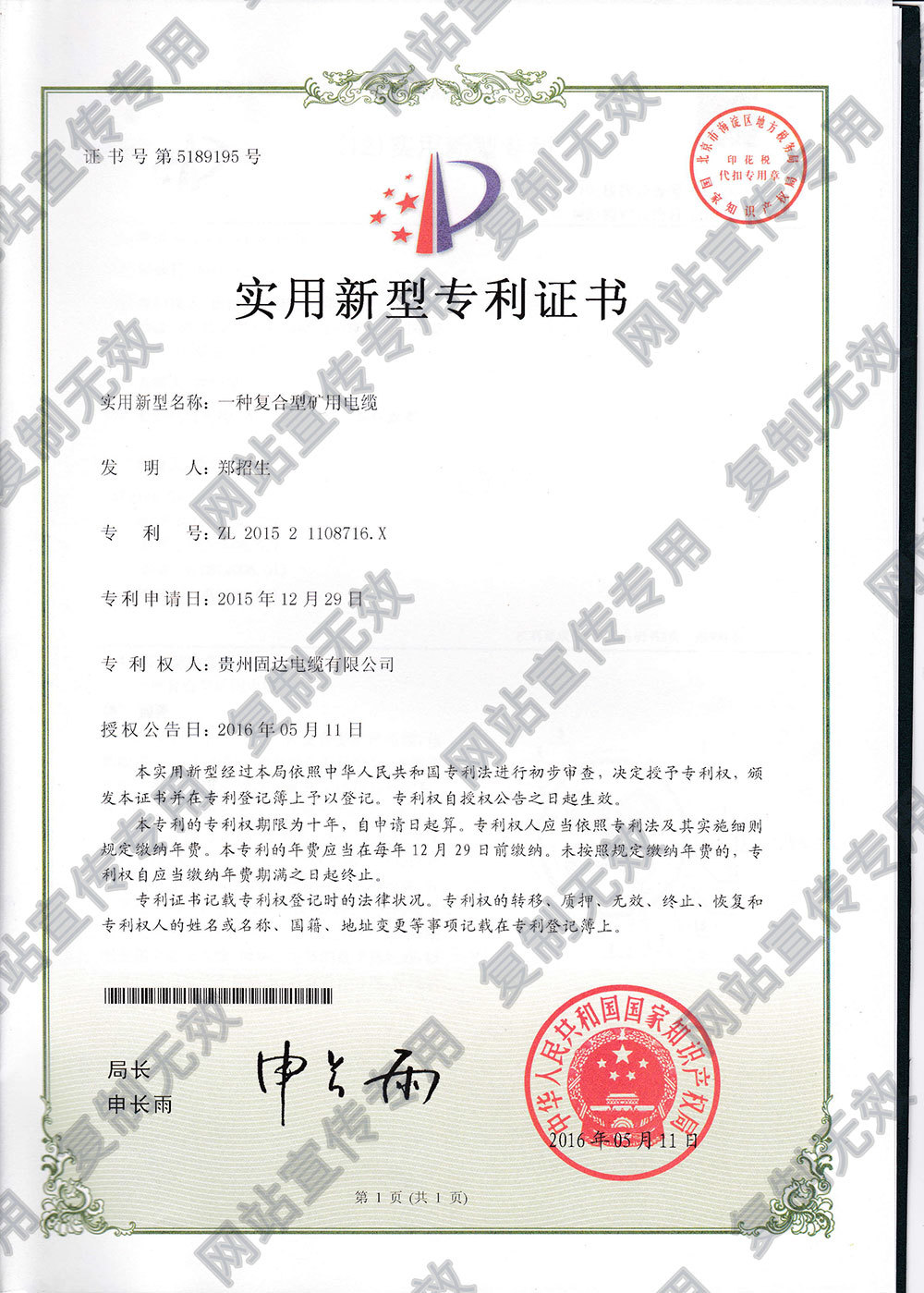

Patent for a composite mine cable

Patent of aluminum alloy high temperature resistant fireproof cable

Patent of a tensile plane spring wire

Patent for a compact mine cable

Patent for a composite telephone line

Patent for pull-resistant earphone wire

Patent for self-locking connector socket of cable

Heating cable patent capable of real-time monitoring

Patent of anti-pressure mine cable

Patent for a double-conducting carbon fiber heating cable

8-shaped spring cable patent

Patent for a special cable used in automobiles

An Improved Multi-function Cable Stripping Machine Patent

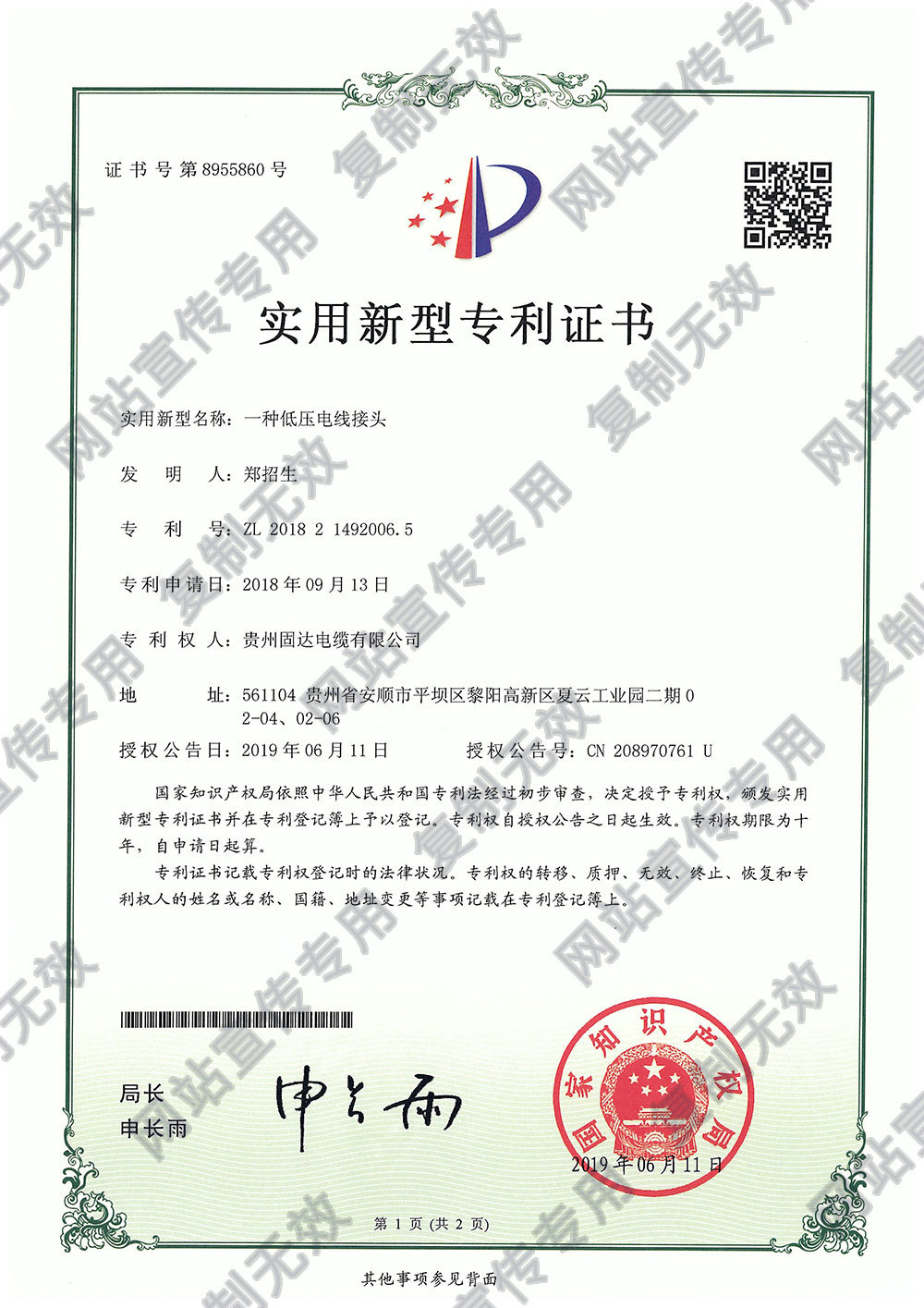

Patent for a low-voltage wire joint

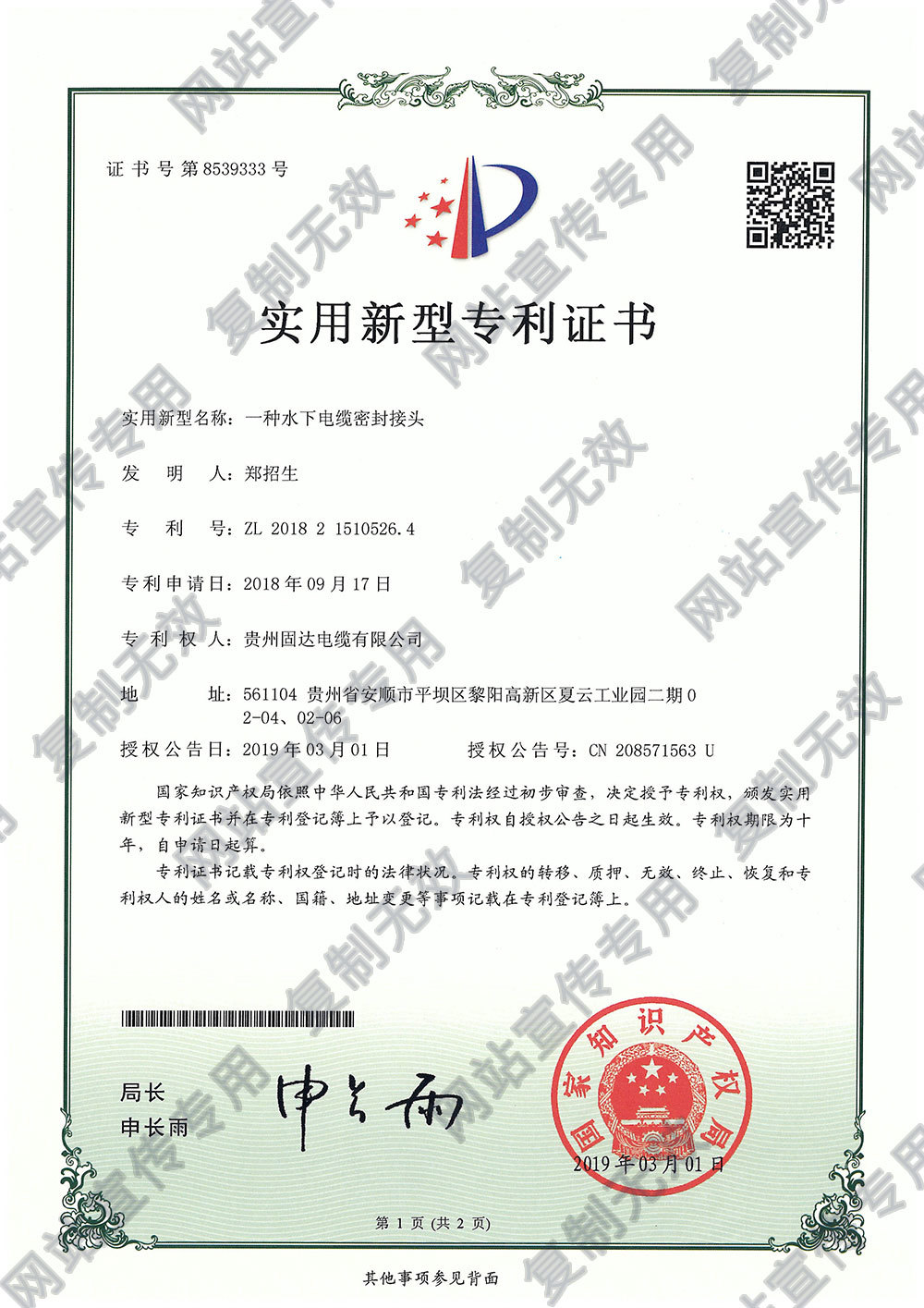

Patent for underwater cable sealing joint

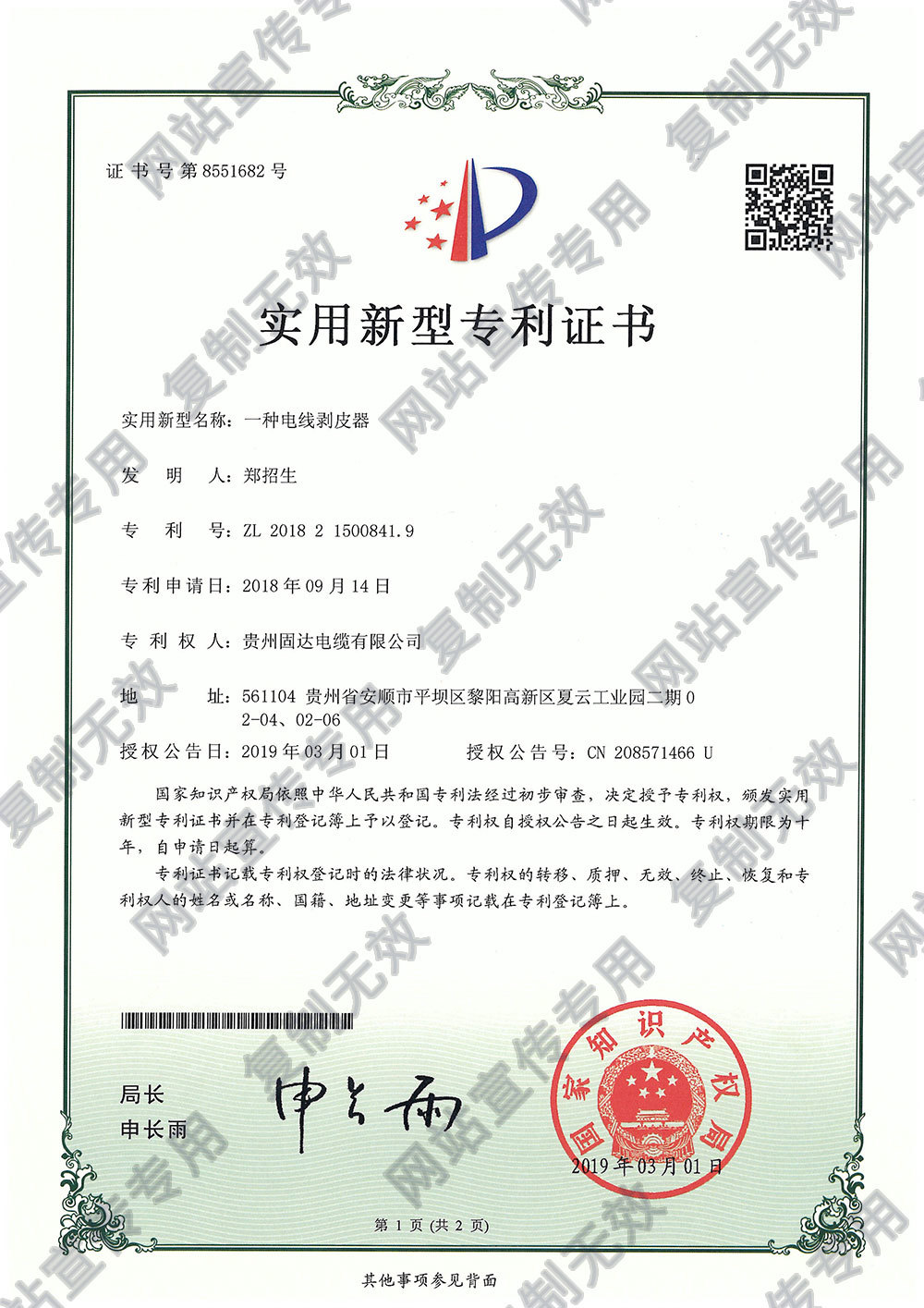

Patent for wire stripper

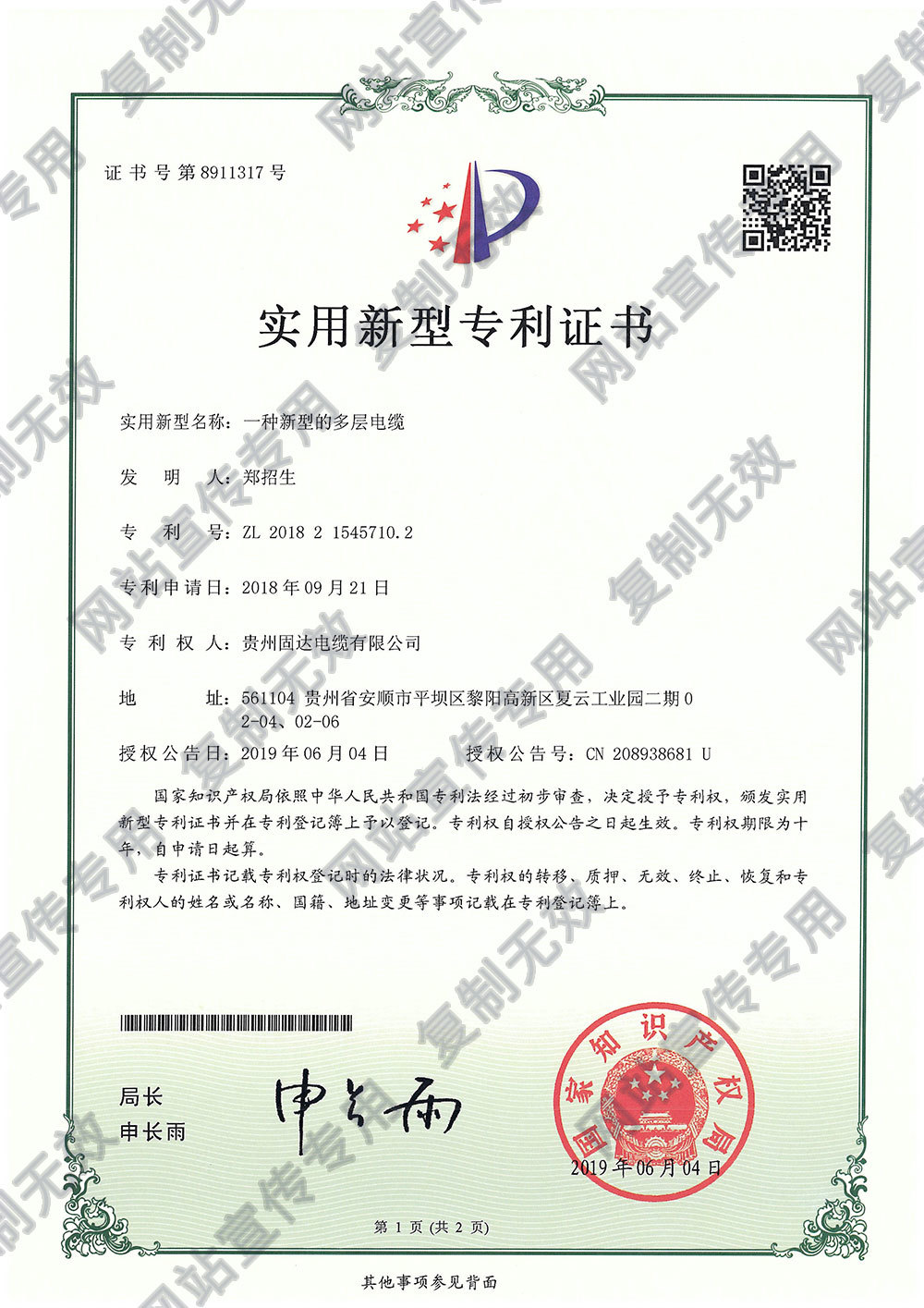

Patent for a new type of multilayer cable

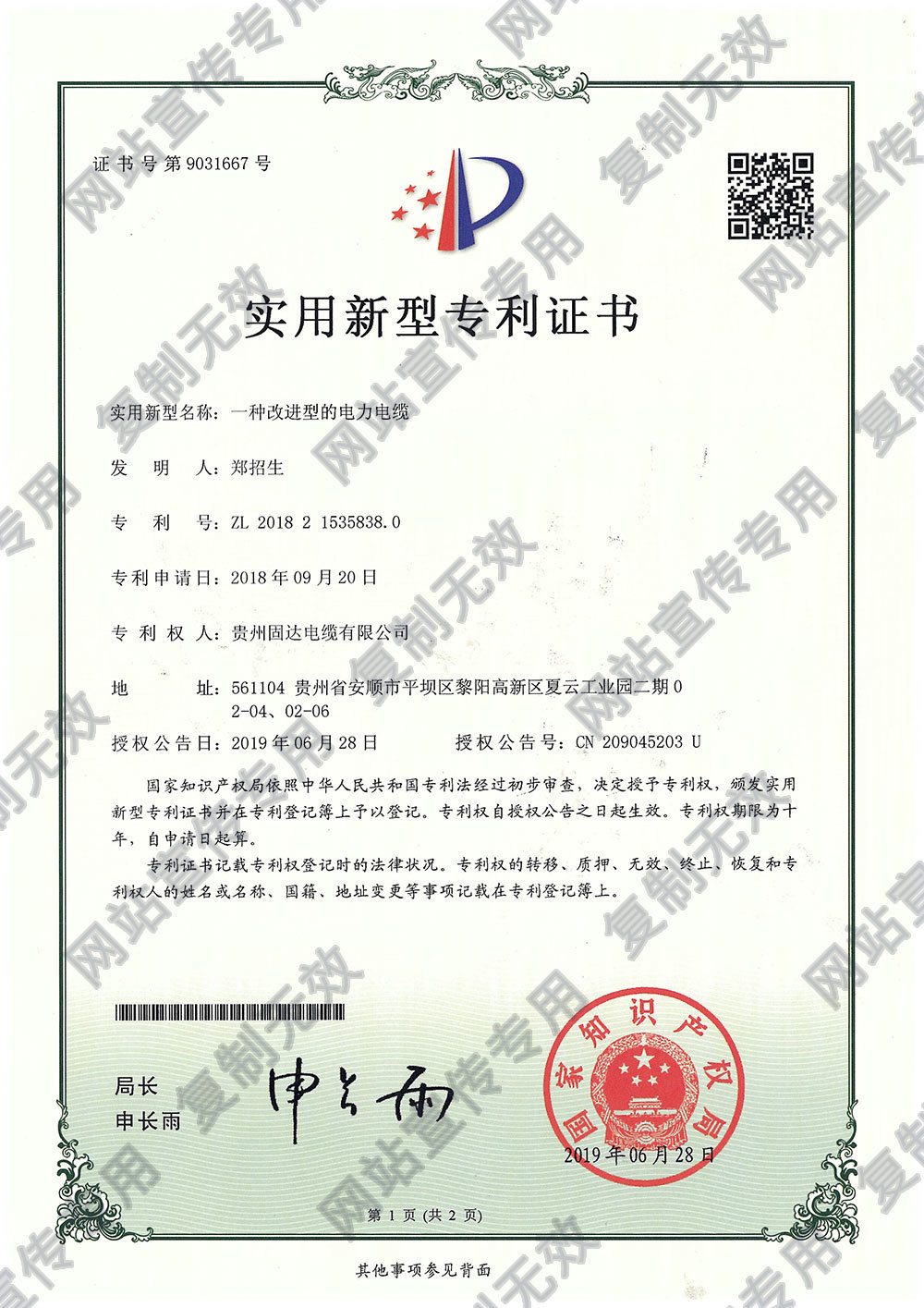

An improved power cable patent

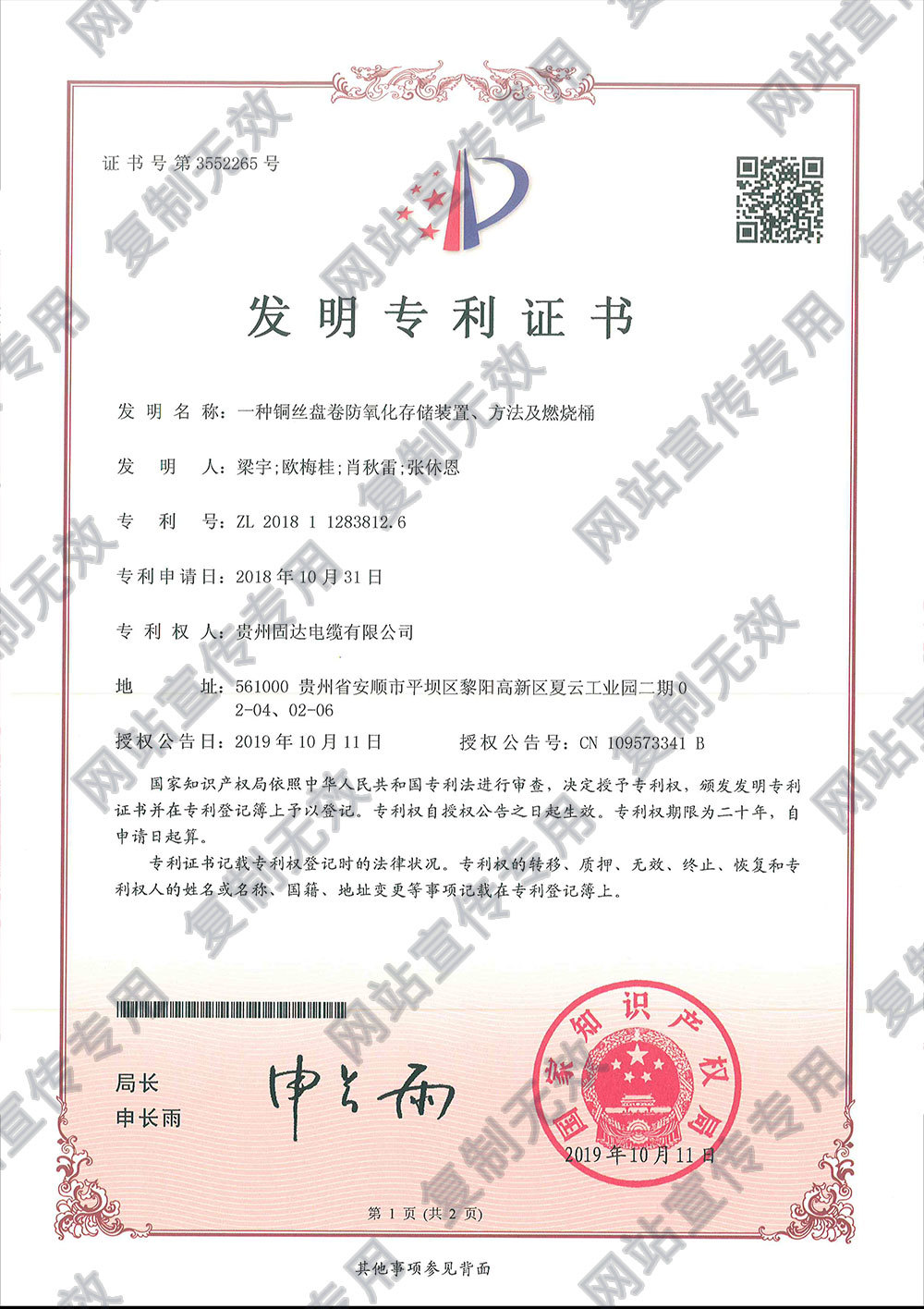

Copper wire coil anti-oxidation storage device, method and combustion barrel patent

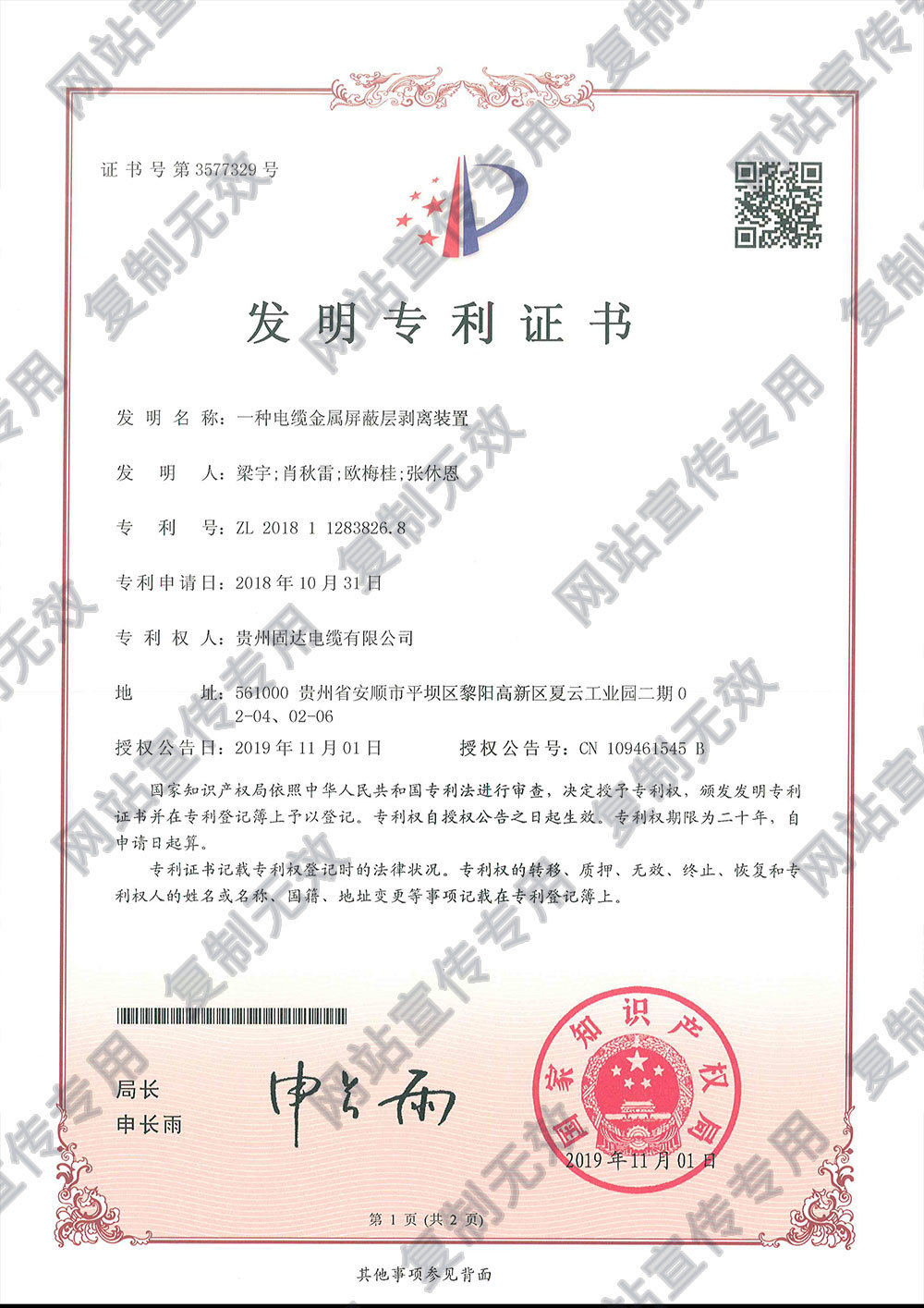

Patent of cable metal shielding layer stripping device

WeChat Sweep to Learn More Guda Information

-

E-mail:guda@188.com

Website:www.gzgddl.com

Consumer Hotline:400-8379-000

Wire Anti-Counterfeiting and Red Packet Inquiries:18185354668

-

Sales Hotline:0851-34754829、0851-34754819

-

0851-34754816

-

After-Sales Service:17630129055

Recruitment Hotline:18385386544

Advertising Cooperation:18166782513

Address: 02-04, 02-06, Xiayun Industrial Park II, Liyang High-Tech Zone, Pingba District, Anshun City, Guizhou Province

Copyright© Guda Wire and Cable (Group) Co., Ltd. 2024. Website Construction: www.300.cn - GuiYang | Cloud News | City Branches |  贵公网安备 52040002000107号 固达电缆.网址

贵公网安备 52040002000107号 固达电缆.网址

SAF Coolest v1.3.1.2 设置面板 PJBSD-ZDIA-SDXZE-ZQZ

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page